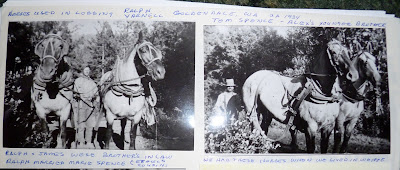

My dear, sweet Aunt Ethel sent me some old family photographs recently. Of primary interest to me were the ones of my Granddad and his team of logging horses. The photos date from some time in the 1930’s and they are a reminder of an era long gone. There are few…, if any…, occupations in life that I could imagine as being more satisfying than working beside and behind horses all day and attending to their care and feeding in the evening after a hard and productive day’s work. But I will never know that satisfaction…, because, “those jobs have been shipped overseas”. Whoops…, excuse me…, it seems that I have read and heard that phrase so many times that it just pops out on its own. And the image of Granddad sending his horses over to China so some low wage coolies could cut the timber and drive the team and save him a little money compared to a high paid American worker and lower his tax base as well, that is precisely the image a lot of folks want you to believe in.

My dear, sweet Aunt Ethel sent me some old family photographs recently. Of primary interest to me were the ones of my Granddad and his team of logging horses. The photos date from some time in the 1930’s and they are a reminder of an era long gone. There are few…, if any…, occupations in life that I could imagine as being more satisfying than working beside and behind horses all day and attending to their care and feeding in the evening after a hard and productive day’s work. But I will never know that satisfaction…, because, “those jobs have been shipped overseas”. Whoops…, excuse me…, it seems that I have read and heard that phrase so many times that it just pops out on its own. And the image of Granddad sending his horses over to China so some low wage coolies could cut the timber and drive the team and save him a little money compared to a high paid American worker and lower his tax base as well, that is precisely the image a lot of folks want you to believe in. Back in Granddad’s day it took a dozen men with cross-cut saws and axes to fell and buck trees into log lengths that could be yarded out by one team of horses in a day. Yeah…, I am glad that Granddad “shipped those jobs overseas”. Whoops, again…, I just meant to say that I am far too old to be engaging in that magnitude of manual labor these days. In my Dad’s day, the horses had been replaced by Caterpillar tractors (Cats we called them) and the cross-cut ‘misery whip” saws and axes had been replaced by motorized power saws. Production probably increased 10 fold..., if not more..., and employed just two or three men with that transition. There was one old logging tradition that I wish was still in practice that ended during Dad’s era…, the Clearwater River log drive. Every spring from 1928 to 1971 when the snows were melting in the high country and the river was rising, millions of board feet of logs were floated nearly 100 miles down the river from the nearly inaccessible stretches of the North Fork of the Clearwater River to the mill in Lewiston, ID on the main fork of the river. An intrepid crew of loggers floated the river behind the logs in wooden dories in the early days, then in later years, outboard motor boats, then jet boats, making sure that the logs didn’t get hung up…, and if they did the loggers gave them the necessary manual help to get them on down to the mill. That job might come close to being as satisfying as horse logging…, especially the five star, all you can eat, hot meals that were served up three times a day on the floating wanigan that served as cook shack and bunkhouse every day. But I will never know that satisfaction…, because “those jobs have been shipped overseas”.

Throughout the 60’s, Dad was a contract logger with a couple of old 1950’s era Cat’s, a couple of old trucks and an old line loader. We always had plenty to eat and as far as I could tell, my brother Larry and I had more and better toys than most of our peers. But my Mom took a job as a school bus driver in the mid-60’s and couple years later took a job at the new plywood plant at Pierce when they first started hiring women. Dad always dreamed of buying new, more technologically advanced equipment like a Cat with power shift transmission, free-spooling winch, hydraulic blade..., or one of the rubber-tired skidders that were just coming onto the market..., but it never happened. Larry and I learned the logging trade during the summer “vacations” from school on that old equipment. At first being more in the way than useful..., but later filling a real position.

The early 1970’s were most likely the height of glory days of logging. In the Weippe-Pierce-Orofino area there must have been close to a dozen different sawmills. In 1970, the year I graduated from high school, there were guys working at the plywood mill before they got out of school. if you could fog a mirror you could get a job. The Vietnam War was employing a lot of the workforce. I never saw the The War..., but I was employed by the Army via the draft in the early 70‘s. When I returned to Idaho in the mid-70’s, things had changed. My Dad had given up contracting with his old equipment. I had to find work elsewhere, which still wasn’t much of a problem because I had learned multiple skills from Dad. I still remember eating lunch with my new boss Charlie “Red” McCollister, as he sat with his stopwatch, timing the first helicopter logging operation going on across the canyon from us. My job that spring was clearing roads of slides and snow drifts with an old Cat so we could get to the timber. The helicopters didn’t need roads..., those road building jobs would soon be “shipped overseas”..., along with all those sawmill jobs. Today Idaho has one of the highest unemployment rates in the country..., and there are just two sawmills left around the Weippe-Pierce-Orofino area.

During the 80’s my brother Larry and I decided to get rich contract logging and bought an old Skagit yarder. We had good years and bad, depending on if we had work for the machine. During the times that we didn’t, we both managed to find other jobs to tide us over until we found more work for our machine. It was getting tougher though, and I didn’t like the uncertainty of that lifestyle. In 1987 I went to Forks, WA to cut timber during our normal spring lay-off in Idaho. I liked it in Forks and we had the Skagit and other equipment we acquired paid off, so I decided to sell out to Larry and ended up staying in Forks. There were three saw shops in Forks, three parts houses, six bars and restaurants..., and plenty of work. For a while.

By the 90’s things were significantly slowing down. To hear most of the folks in Forks tell it, the problem was the spotted owl controversy..., but in reality, there were many factors that I was oblivious to at the time. Off to southeast Alaska I went. Julie followed along behind me and we spent four seasons in a cracker box size camper in a remote logging camp on Prince of Wales Island. The slow down in the timber industry made it to Alaska..., not far behind us..., and we returned home to Forks. I found work cutting timber again..., but the writing was on the wall..., that even I could read by then. The first four years I had been in Forks I had seldom worked more than a half hour ride to work and I was mostly cutting big export grade timber. In 1994 I was riding two hours to work..., and back..., and cutting second growth timber. There was one saw shop in Forks, one parts house, half the number of bars and restaurants. It was time to make a serious, structural change in my lifestyle. All those timber jobs were being “shipped overseas”.

Yeah..., I am being quite factious here. OK..., call it hyperbole if you like..., but my point is, that the timber industry is indicative of the loss of the manufacturing jobs that have been plaguing this country for three decades. My brother Larry tells me that his son Bert, with a tree processing machine, can fell and buck ten times the number of logs I ever cut on my best day with a power saw. The buzz phrase that we keep hearing from nearly all the pundits is that we are “shipping our jobs overseas”. I am about sick of hearing that (and hope you are too) by now. That may be the case in some instances, but if we don’t face up to the fact that technology and resource extraction are the structural causes of these job losses, we aren’t going to solve the problem. If the powers that be continue to dump money on this problem they don’t even understand..., if they think all that money is somehow going to “stimulate the economy” and bring all those “jobs back from overseas”..., we are in a world of hurt.

I applaud the Occupy Wall Street (OWS) protests. There are many problems in this country..., and the world..., that need addressing. But I am afraid that since it seems to be primarily the Millennial Generation orchestrating the protests..., that they aren’t aware that the jobs problem isn’t just about “shipping jobs overseas”. But..., it seems that no one else is aware of it either.

I don’t have any answers or ideas regarding how we are going to solve this problem. I have a feeling that it will solve itself soon..., and I may have one of my dream jobs after all. But I am going to stash some saw gas..., I want nothing to do with those old cross-cut saws. They can “keep those jobs overseas”.

I first posted this one over at The Agonist on 11/6/11

ReplyDeletehttp://agonist.org/shipping_our_jobs_overseas/

and there were some good comments..., but some doubted my contention that technology caused far more job loss than "shipping our jobs overseas"..., so I linked to this academic study below.

http://media.clemson.edu/public/cit/citpaper12.pdf

Manufacturing Productivity and the Shifting US,

China, and Global Job Scenes—1990 to 2005

William A. Ward

Professor of Applied Economics and Statistics & Director of the Center for International Trade Clemson University

Clemson University Center for International Trade Working Paper 052507 (August 4, 2005)

Executive Summary Summary of Section I Results:

Manufacturing productivity growth from 1990 to 2004 should have taken away 7.5 million of the 17.7 million manufacturing jobs that existed in the US in 1990, while GDP growth should have added back (at the new productivity levels of 2004) 5.7 million manufacturing jobs—for a net loss of 1.8 million. In fact, the US economy lost 3.3 million manufacturing jobs during that period, implying that structural and competitive factors shifted 1.5 million of the GDP-growth-implied jobs from the manufacturing sector to other sectors of the US economy. I applied this same "Job Shift Analysis" to the sub-periods 1990-1995, 1995-2000, and 2000-2004 and found striking differences between those intervals in terms of manufacturing employment changes (and job quality changes—Section II). For one thing, more than 80% of the manufacturing job losses by the US economy since 1990 occurred after 2000. I find that 100% of the (3.0 million) manufacturing jobs lost since 2000 were lost to manufacturing productivity growth and that 100% of the (1.8 million) jobs that should have been added back by GDP growth in the US after 2000 were shifted to other sectors of the US economy than manufacturing.

(continued in next comment section)

Section IV Conclusions. While certain US manufacturers might compete globally in coming years, manufacturing is not likely to contribute to net job creation in the US the way it did at mid-century. I expect two factors to continue to reduce manufacturing employment globally: (a) Manufacturing productivity growth, and (b) Structural changes in demand away from goods and towards services, at the margin.

ReplyDelete…

In this paper, I argue that one must be careful in seeing a one-to-one relationship between China's export growth and US job losses in manufacturing. No doubt, there is some relationship (particularly after 2000). But it is not one-to-one. The emergence of China as the world's low-cost manufacturing center is part of a broader story of restructuring that is occurring in the manufacturing sector globally. That restructuring process is triggering massive change that is showing up in productivity growth and manufacturing employment declines globally as well as in the US.

In following sections of this paper, I present data and calculations to buttress the argument that US manufacturing job losses arise from three, interacting factors and that those three factors are having similar effect on manufacturing employment in other countries as well: (1) Productivity growth in the manufacturing sector, (2) Growth in GDP and in personal consumption expenditures that favor service consumption over goods consumption at the margin, and (3) De-integration, de-centralization, and re- organization of manufacturing production processes. The third of the ”global re- organization of production processes” is related to the argument that jobs are leaving for other countries; but the actual process that is at play here is vastly different from those envisioned in the urban legends that make up much of the popular discourse on trade and jobs.

…

Meanwhile, compare the United States economy's 1.5 million manufacturing job losses from competitive and structural factors to the 7.5 million lost to productivity growth. From this comparison, I conclude that, during the period 1990 to early-2005, US manufacturing productivity growth cost the US several times more manufacturing jobs than all other factors combined, including global competition.

…

As many other analysts already have pointed out, manufacturing will not be the job creator in the early years of the 21st century in the US that it was during much of the 20th century. In addition "manufacturing competitiveness" is not likely to mean the same thing as "job creation" in coming years, as much of that competitiveness will require cost reductions (read ˜labor reduction") and switching to production of higher valued products that do not entail much labor per unit of output. The era of job creation through "industrialization" (i.e., manufacturing) in the US appears to be over. Again, as others have suggested, we must now find new ways to achieve employment and income growth. Not just because we are in the US, a high-income country with a powerful currency. But also because we are part of a broader economy in which dramatic manufacturing productivity growth and structural changes in demand and in production organization are global, not just national phenomena. On the academic research side, our models must begin to reflect these realities, and (as the BLS is beginning to do) we must focus greater attention to building the global datasets that we will need to accomplish such changes.